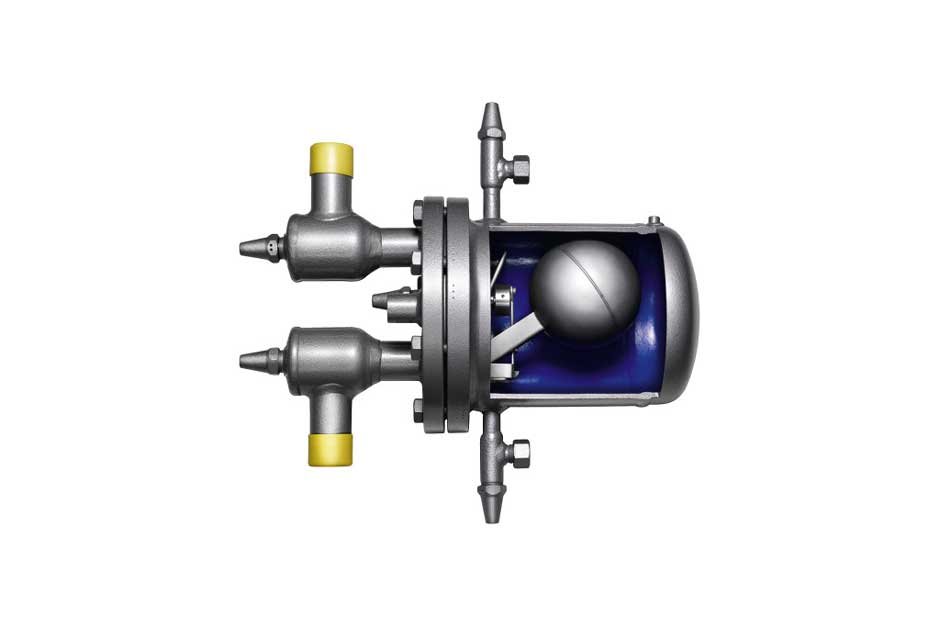

Float valves maintain fluid levels in tanks and pipelines across various manufacturing systems. When working correctly, these valves help prevent overflow and protect equipment from damage. But like any component in an industrial setting, float valves can lose efficiency without proper attention. Here’s how to get the most out of each float valve and keep operations running without interruption.

1. Choose the Right Material for the Environment

Every manufacturing system has different requirements. A valve operating in a corrosive chemical tank will need different materials than one used in a freshwater system. Stainless steel offers durability in harsh environments, while PVC works well in low-pressure or chemical-resistant settings. Matching the float valve to the operating conditions improves lifespan and performance from the start.

2. Maintain Proper Alignment

Incorrect alignment during installation can lead to premature wear or valve failure. Keep in mind that a misaligned float arm may drag or bind, disrupting movement and accuracy. Always check alignment against manufacturer specifications. In addition to that, you should use a level and visual inspection to ensure the float moves freely within the intended range without resistance.

3. Inspect for Mineral Buildup and Debris

Over time, float valves can collect scale and other residues. In areas with hard water or high particulate content, this buildup can interfere with valve movement or block flow paths. Regular inspection and cleaning prevent issues before they impact performance. Using a soft brush or cloth works well to remove surface buildup. For stubborn deposits, use a descaling solution approved for the valve material.

4. Test Float Buoyancy Periodically

Take note that a float’s ability to rise and fall with the fluid level directly impacts how well the valve operates. Having a cracked or waterlogged float won’t maintain proper buoyancy, causing delayed or incomplete valve action. Regular buoyancy checks can catch problems early. Simply remove the float and submerge it in clean water. If it sinks or shows signs of internal water, replace it immediately.

5. Use Proper Valve Sizing for Flow Demand

Going for a float valve that’s too small won’t keep up with flow demands, while an oversized one might cycle too frequently. Either case reduces efficiency and increases wear. Determine the required flow rate and match it with a valve that can handle the volume without strain. Aside from that, think about pressure ratings to avoid overloading the valve during peak operation.

6. Calibrate for Accurate Shutoff Points

Each float valve includes an adjustment mechanism that sets when the valve opens and closes. Improper calibration may cause the system to shut off too early or too late. Don’t forget to use gradual adjustments and observe tank levels during operation. What’s more is that fine-tuning helps prevent overflows or underfills, both of which can disrupt the manufacturing process or damage equipment.

7. Establish a Regular Maintenance Schedule

Investing in a float valve may look simple, but it performs a critical job. Like any moving part, it benefits from routine maintenance. Set up a maintenance schedule that includes cleaning, calibration, and testing. Log any repairs or replacements to track performance. A well-maintained float valve provides:

- Reliable results

- Extends equipment life

- Reduces costly downtime

Maximize Efficiency, Minimize Downtime!

Getting the most out of a float valve doesn’t require complicated tools or excessive downtime. Just a little attention to materials and flow capacity can make a difference. When float valves perform correctly, fluid levels stay consistent, systems run smoother, and maintenance crews have fewer headaches. With these tips, manufacturing systems can rely on float valves to do the job right, day after day.

Leave a Reply