Quick Navigation Bar

- Core positioning and technological generational differences

- Key Performance Parameters and Technical Comparison

III.Real-World Performance: Fuel Consumption, Reliability, And Cost

IV.The Ultimate Decision-Making Guide: Who Should Choose Whom?

- For truck drivers on the road, repair shops ensuring smooth fleet operations, parts stores supplying the “lifeblood” of vehicles, and cost-conscious logistics company decision-makers, choosing an efficient, reliable, and economical engine directly impacts the core of operational efficiency.

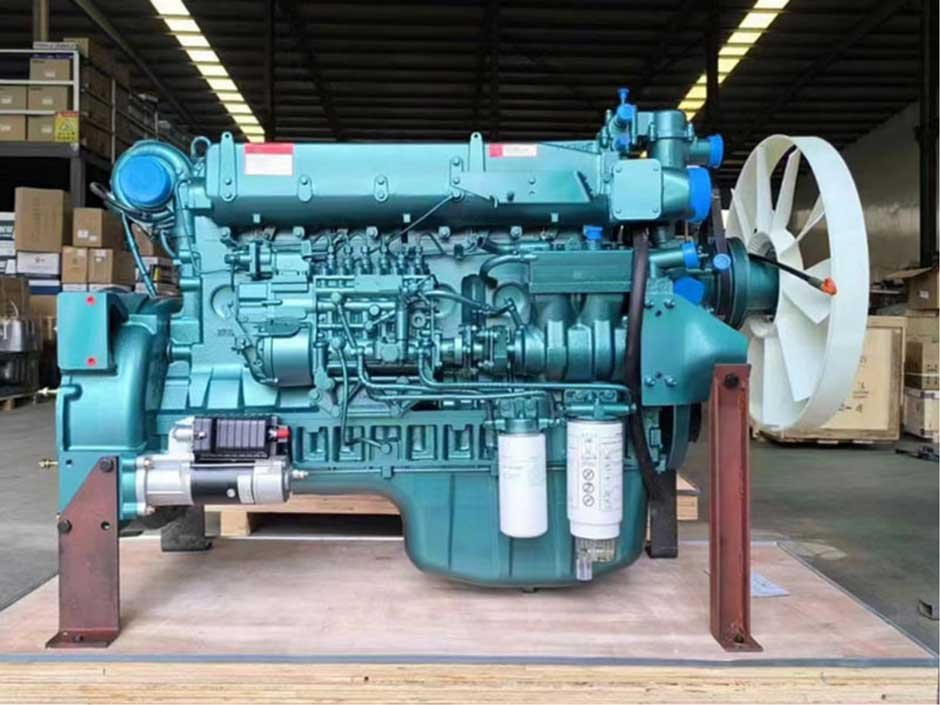

- The Howo 371 Engine And Howo 380 Engine Models in China National Heavy Duty Truck Group’s HOWO series often attract attention, as they appear similar but actually have key differences. Selecting the wrong model could result in higher fuel costs, unexpected maintenance downtime, or even losing transportation orders due to non-compliance with emissions standards.

I. Core positioning and technological generational differences

HOWO 371 Engine:

Technical Platform: Developed based on a mature National V emission standard technical platform.

Core Objective: While meeting the strict emission regulations at the time, it provides stable and reliable power output and good fuel economy, making it one of the main power sources for HOWO heavy-duty trucks (such as the A7 series) during the National V phase.

Features: Relatively mature technology, long market validation period, well-established maintenance system, ample spare parts supply, and relatively low costs.

HOWO 380 Engine:

Technical Platform: Developed based on a more advanced National VI emission standard technical platform.

Core Objective: To meet the current most stringent National VIb emission regulations, and on this basis, optimize combustion efficiency, reduce fuel consumption, enhance power response, and improve reliability through technological upgrades.

Features: Represents Sinotruk’s latest technology, integrating systems such as high-pressure common rail, efficient turbocharging, and advanced aftertreatment (DOC+DPF+SCR), offering greater environmental friendliness, efficiency, and intelligence (typically incorporating more sensors and electronic control functions).

II. Key Performance Parameters and Technical Comparison

| Features | HOWO 371 Engine (National V) | HOWO 380 Engine (National VI) |

| Displacement | ≈ 11.0X liters (common in HW19710) | ≈ 11.0X liters (e.g., MC11H.38-60) |

| Rated power | ≈ 371 horsepower (273kW) | ≈ 380 horsepower (279kW) |

| Maximum torque | ≈ approximately 1800 Nm | ≈ Approximately 1900 Nm |

| Emission standards | National V | National VI B |

| Aftertreatment system | SCR (Selective Catalytic Reduction) | DOC+DPF+SCR integrated system |

| Fuel system | High-pressure common rail | Upgraded high-pressure common rail (higher pressure, more precise control) |

| Technical highlights | Mature and stable | Intelligent electronic control, efficient turbocharging, low-friction technology |

| Maintenance complexity | Relatively simple | Significantly improved |

| Parts cost | Relatively low (abundant market inventory) | Relatively high (new system, new components) |

| Compatible models | National V-compliant HOWO heavy-duty trucks (e.g., older A7/T7 models) | National VI stage HOWO full-series heavy-duty trucks (e.g., TH7/TX series) |

III.Real-World Performance: Fuel Consumption, Reliability, And Cost

Fuel efficiency (fuel consumption per 100 km):

- Theoretical performance: Thanks to more precise combustion control, low-friction technology, and optimized power curves, the HOWO 380 typically achieves 3-8% better fuel efficiency than the 371 under the same conditions (standard load, high speed). One of the core objectives of the National VI technology upgrade is to improve energy efficiency.

- Actual case: A logistics company engaged in flatland highway standard load transportation (49 tons) reported that under the same route and driving habits, the average fuel consumption of the 371 fleet was approximately 37.5 L/100 km. After switching to the new National VI 380 models, the average fuel consumption decreased to approximately 35.8 L/100 km.

- Key influencing factors: Driving habits (smooth driving highlights the fuel efficiency advantage of the 380), operating conditions (mountainous terrain, heavy loads, and frequent starts/stops may narrow the gap or even reverse it), and aftertreatment system status (DPF blockage in the 380 can significantly increase fuel consumption). Fuel quality is the lifeline of the 380!

Reliability & Maintenance:

- Howo 371 Engine: Advantages include relatively simple structure, thorough market validation, widespread repair technology, and slightly higher tolerance for fuel/urea. Common issues mainly revolve around traditional mechanical components and the SCR system. Disadvantages include relatively outdated technology.

- HOWO 380: Advantages include updated design and materials, resulting in lower theoretical failure rates (especially for the engine block). Disadvantages include an extremely sensitive and complex aftertreatment system (DPF), which is the primary failure point:

- DPF clogging/regeneration failures: Caused by prolonged low-speed operation, use of low-quality fuel/urea, or interrupted regeneration. Repair costs are high, and severe cases may require replacement of the entire DPF assembly.

- Sensor failures: More sensors mean more potential failure points.

- Strict maintenance requirements: Must use National VI-compliant low-ash engine oil (CK-4/CJ-4 or higher), otherwise the DPF will clog rapidly. Must use qualified automotive urea. Maintenance intervals and operations must strictly follow the manual.

Total Cost of Ownership (TCO):

- Initial purchase cost: New vehicles equipped with the 380 engine under the National VI emissions standard are significantly more expensive than the National V 371 models from the same year (primarily due to the cost of the aftertreatment system).

- Fuel costs: The fuel efficiency advantage of the 380 model gradually offsets or even exceeds the purchase price difference when operating mileage is sufficiently long. The higher the fuel price and the greater the mileage, the more evident the economic advantage becomes.

- Maintenance and servicing costs: The 380 model has higher routine maintenance costs (especially for specialized engine oil) and potential aftertreatment system repair costs. Damage to the DPF caused by low-quality fuel can result in significant costs.

- Residual value: The long-term residual value of the National VI 380 model is expected to be significantly higher than that of the National V 371 model. As the phase-out of National V vehicles accelerates, the liquidity and value of used 371 models will decline significantly.

- Road access rights: The National VI status of the 380 model ensures broader and longer-term road access rights, avoiding missed business opportunities due to emission restrictions.

IV.The Ultimate Decision-Making Guide: Who Should Choose Whom?

Choosing the Howo 371 Engine (National V used vehicle/existing vehicle) is more suitable for:

- Those with extremely limited budgets, primarily considering the short-term (1-3 years) purchase or used vehicle investment costs.

- Operating regions with no immediate risk of National V emission restrictions (local policies must be closely monitored).

- Existing maintenance teams are familiar with National V technology but face challenges in upgrading to National VI maintenance capabilities.

- Relatively low sensitivity to fuel costs or very short operational mileage.

- Parts stores: Serving a large fleet of National V HOWO vehicles, demand for 371 parts remains strong in the short term.

Choosing the HOWO 380 (National VI new vehicle) is a wise decision:

- Planning to purchase a new vehicle for long-term (over 5 years) stable operation.

- Operating routes cover major cities or environmentally sensitive areas, requiring guaranteed long-term road access rights.

- Highly prioritizing fuel efficiency, with long operating mileage, and willing to recover initial investments through fuel savings.

- Capable of and committed to strictly adhering to National VI maintenance standards (using dedicated engine oil, qualified urea, and proper driving/regeneration practices).

- Logistics companies aiming to establish a green fleet image aligned with environmental trends.

- Service stations: Investing in the future requires mastering National VI (especially aftertreatment) repair technologies to attract high-end customers.

- Parts stores: Proactively stocking National VI vehicle parts (particularly aftertreatment-related consumables, sensors, and dedicated fluids).

V. Important Reminders and Expert Recommendations

- The lifeline of the National VI 380: fuel and urea! It is essential to refuel with diesel that meets National VI standards at authorized gas stations. Only certified high-quality automotive urea solution (such as Kalan Su, Kunlun Star, etc.) should be used. A single instance of using low-quality fuel or urea could result in thousands, or even tens of thousands, of dollars in aftertreatment repair costs!

- Specialized engine oil is a mandatory requirement: When maintaining the National VI 380, it is essential to use heavy-duty diesel engine oil that meets the API CK-4/CJ-4 or ACEA E6/E9 standards with low ash content (Sulphated Ash <1.0%). This is critical for protecting the DPF!

- Understand and respect regeneration: Learn about the DPF regeneration indicator light on the dashboard. When regeneration is required while driving, maintain a high RPM (e.g., above 1,500 RPM) for a period of time to complete the regeneration process. Do not interrupt the regeneration process arbitrarily. If a parking regeneration request occurs, perform the operation as soon as possible in a safe, open area.

- Choose professional maintenance: For issues with the 380, especially those related to the aftertreatment and electronic control systems, it is essential to select a service station equipped with professional diagnostic equipment and staffed by technicians certified for National VI standards. Roadside shops may cause further damage.

- Driver training is critical: Logistics company owners and fleet managers must provide drivers with training on proper operation of National VI vehicles and regeneration procedures. Driving habits directly impact fuel consumption and the lifespan of the aftertreatment system.

VI. Conclusion

- The Howo 371 Engine And Howo 380 Engine represent two distinct eras in heavy-duty truck power. The Howo 371 Engine, as a mature National V-compliant model, still holds value in the existing market, particularly suited for scenarios with limited budgets and short-term operations. However, looking to the future, the National VI technology represented by the HOWO 380 is undoubtedly the inevitable choice.

- It offers overwhelming advantages in terms of power performance, environmental friendliness, long-term economic efficiency (fuel savings), and road rights protection, despite imposing higher requirements on fuel quality, maintenance, and repairs.

keywords: Sinotruk Howo Parts/Howo 371 Engine/Howo 371 Engine Parts/Howo 371 Engine Supplier/Howo 371 Engine Manufacturer/Howo 371 Engine For Sale/Howo 371 Engine Price/Howo 371 Engine Factory/Howo 371 Engine Importers/Howo 371 Engine Distributor/Buy Howo 371 Engine/Howo 380 Engine/Howo 380 Engine Factory/Howo 380 Engine Supplier/Howo 380 Engine Manufacturer/Howo 380 Engine For Sale/Howo 380 Engine Price/Buy Howo 380 Engine

Leave a Reply