The Problem with “Throwaway” Culture

We all know the feeling: Our favorite pair of sandals gives up the ghost. Maybe the sole flaps or a strap tears. Too often, we toss them aside. This “throwaway” culture fills landfills and harms our planet.

But what if there was another way? What if we could save our beloved footwear? What if repair were easy and sustainable?

This article explores the power of shoe repair and how fixing things can fight waste. We will also explore the idea of a circular economy and see how businesses can thrive by helping us keep what we love.

We’ll share insights from NuShoe, a company that has been repairing shoes for decades. Their success shows how craftsmanship and care can change the world, one shoe at a time.

For too long, our modern consumer society has accepted a linear economic model: take, make, dispose. While seemingly convenient, this approach carries a heavy environmental burden. Nowhere is this more evident than in the fashion industry, where “fast fashion” has accelerated consumption and, consequently, waste. Footwear, a seemingly small component of our daily lives, contributes significantly to this problem.

Consider the sheer volume of textile waste generated globally. Millions of tons of clothing and footwear end up in landfills each year, where they can take hundreds of years to decompose, releasing harmful greenhouse gases and leaching toxic chemicals into the soil and groundwater. The production of new shoes itself is resource-intensive. It requires vast amounts of water, energy, and raw materials, from petroleum-derived synthetics to animal hides, often sourced through environmentally damaging practices. The dyeing and finishing processes involve chemicals, which can pollute waterways if not appropriately managed.

Planned obsolescence, a strategy where products are designed to have a limited lifespan, further exacerbates this issue. While a shoe might appear durable, subtle design choices or material selections can subtly reduce its longevity, pushing consumers to replace items more frequently than necessary. This continuous cycle of production and disposal places immense pressure on our planet’s finite resources and fragile ecosystems. In essence, we borrow from future generations to satisfy our immediate desires, creating an unsustainable trajectory for our planet.

The Shift to a Circular Economy

Fortunately, a growing awareness of these environmental challenges catalyzes a fundamental shift in how we approach consumption and production. The linear “take-make-dispose” model is gradually giving way to the principles of a circular economy. This paradigm emphasizes keeping resources in use for as long as possible, extracting their maximum value, then recovering and regenerating products and materials at the end of each service life.

A confluence of factors drives this shift. Market trends indicate a burgeoning consumer demand for sustainability. Increasingly, individuals seek brands that align with their values, prioritizing environmental responsibility and ethical practices. This isn’t just a niche market; it’s a mainstream movement, with consumers actively looking for ways to reduce their ecological footprint.

The core tenets of the circular economy can be summarized as “Reduce, Reuse, Repair, Recycle.” While all four R’s are crucial, “Repair” often receives less attention than “Recycle,” yet it holds immense potential. Repairing an item extends its life directly, preventing it from entering the waste stream and delaying the need for new production. This inherently reduces the demand for virgin resources and the energy associated with manufacturing.

From an economic perspective, circular models offer significant benefits. They foster design and material science innovation, create new job opportunities in repair and remanufacturing, and build more resilient supply chains. For businesses, embracing circularity can lead to cost savings through reduced material consumption and waste disposal, improved brand reputation, and increased customer loyalty. Corporate responsibility is no longer just a buzzword; it’s becoming a strategic imperative, with companies recognizing their role in contributing to a more sustainable future.

Key Principles of a Sustainable Business

At the heart of a truly sustainable business model lies a commitment to principles that defy the conventional throwaway culture. These principles guide operations, product development, and customer engagement, positively impacting the environment and society.

- Longevity over Disposability: A sustainable business prioritizes designing and producing items built to last. This means investing in high-quality materials, robust construction, and timeless design. The goal is to maximize the product’s lifespan, reducing the frequency of replacement and, consequently, the environmental impact of new production.

- Resource Conservation: This principle involves minimizing the consumption of virgin resources. It encompasses everything from optimizing manufacturing processes to reduce material waste, exploring recycled or sustainably sourced materials, and, crucially, enabling the repair and reuse of existing products. Every repair saves the resources that would have gone into creating a new item.

- Waste Reduction: Beyond material waste, sustainable businesses strive to minimize waste across all operations – energy, water, and emissions. By focusing on repair, they directly divert items from landfills, changing potential waste into valuable, usable goods.

- Valuing Skilled Labor: Repair is inherently a skilled trade. A sustainable business model recognizes and champions the expertise of artisans and technicians who possess the knowledge and dexterity to breathe new life into worn items. This creates meaningful employment opportunities and preserves traditional crafts that might otherwise fade in a disposable economy.

- Creating a Closed-Loop System: The ultimate aim of a circular economy is a closed-loop system where materials and products are continuously circulated and regenerated. Sustainable businesses contribute by designing for repairability, facilitating collection and refurbishment, and ensuring that materials can be effectively recovered and repurposed at the end of a product’s life. This minimizes reliance on new inputs and eliminates waste outputs.

A Case Study in Sustainable Business: The NuShoe Model

To truly understand the power of these principles in action, we need look no further than NuShoe. For decades, this remarkable company has been a quiet pioneer in sustainable business, demonstrating how dedication to craftsmanship and repair can build a thriving enterprise while simultaneously positively impacting the environment.

Founded in 1994, NuShoe started on a somewhat counter-cultural mission at the time: to extend the life of quality footwear through expert repair. In an era increasingly dominated by mass production and planned obsolescence, NuShoe championed the value of durability and the art of restoration. Their business model is a direct challenge to the linear economy. Instead of encouraging endless consumption of new products, they empower consumers to keep their beloved shoes out of landfills and on their feet.

The scale of NuShoe’s impact is impressive. Since its inception, the company has expertly repaired over 5 million pairs of shoes. This staggering volume represents millions of shoes saved from premature disposal, preventing countless tons of waste and conserving enormous resources that would have been expended in manufacturing replacements. Their process isn’t just a simple patch-up; it’s a comprehensive restoration service often involving resoling, re-stitching, and refurbishing, bringing shoes back to a condition that rivals their original state.

NuShoe’s success is a testament to the viability of a repair-focused economy. They’ve proven a significant market for quality repair services, driven by consumers who appreciate durability, value, and sustainability. By offering an alternative to constant replacement, NuShoe disrupts the traditional consumption cycle, proving that a business can thrive by helping people consume less rather than more.

From Worn Out to Reborn

The change at a repair facility like NuShoe is often miraculous. We’ve seen countless pairs of shoes arrive looking utterly defeated – soles flapping, leather cracked, stitching undone – only to emerge looking and feeling as good as new, sometimes even better. These before-and-after examples are powerful visual testaments to the artisans’ skill and the repair process’s effectiveness.

But the value of repair extends far beyond aesthetics and functionality. For many, shoes are more than just utilitarian objects; they carry memories, represent personal style, or are simply a comfortable, broken-in extension of themselves. Customer testimonials frequently highlight this emotional connection. We hear stories of beloved hiking boots that have traversed mountains, dress shoes worn for significant life events, or comfortable everyday sandals that have become indispensable. Losing such a pair can feel like losing a part of one’s history. Repair offers a way to preserve these connections, allowing individuals to continue their journey with footwear that holds personal significance.

By extending the product lifespan of these cherished items, repair services like NuShoe’s contribute to a more mindful and sustainable approach to consumption. It’s about investing in quality and longevity, rather than succumbing to the fleeting trends of fast fashion. This practice saves money in the long run and fosters a deeper appreciation for the craftsmanship and materials that go into making durable goods.

The Intersection of Craftsmanship and Durability

The ability to repair a shoe effectively is a delicate dance between skilled artisanship and the intelligent application of modern materials. It’s an intersection where traditional cobbling techniques meet contemporary adhesive technologies and advanced repair methods.

Skilled artisans possess an intricate understanding of footwear construction, material properties, and the nuances of various repair challenges. They know how to carefully dismantle, clean, prepare, and reassemble shoes, ensuring that each repair is a temporary fix and a durable, long-lasting solution. This expertise is honed over years of practice, passed down through generations, and continuously adapted to the evolving landscape of shoe design and materials.

The importance of quality materials for repairability cannot be overstated. A well-made shoe, crafted from robust leather, resilient rubber, or durable synthetics, is inherently more amenable to repair than a cheaply constructed, disposable item. The choice of adhesives, for instance, is critical. Different materials, such as the various types of rubber, leather, cork, and synthetic components found in sandals, require specific types of glue that can withstand constant flexing, moisture, and temperature fluctuations. Modern adhesive challenges require Expert sustainable sandal repair knowledge to ensure the proper bond for lasting results. For instance, while super glues (cyanoacrylates) offer quick bonds, they tend to be rigid and brittle, making them unsuitable for flexible areas like shoe soles. On the other hand, Urethane-based glues provide excellent flexibility and strong adhesion, making them ideal for reattaching soles. Neoprene cement, a contact adhesive, is another professional-grade option known for its strong, flexible, and waterproof bond, especially for rubber and leather.

Extending the Life of Iconic Brands

The expertise of repair specialists allows us to extend the life of iconic brands and diverse footwear types that would otherwise be discarded.

- Repairing Dr. Martens: Known for their durable leather and distinctive air-cushioned soles, Dr. Martens boots often see their wear down or separate over time. Expert repair involves carefully removing the old sole, preparing the welt, and attaching a new, usually custom-made, sole that matches the original’s flexibility and durability.

- Resoling Birkenstocks: Birkenstock sandals, beloved for their anatomical cork footbeds, typically wear out in the sole or develop cracks in the cork. Resoling these involves replacing the entire outsole and often repairing or sealing the cork footbed, preserving the customized fit that makes them so comfortable.

- Restoring Leather Boots: With proper care and timely repairs, high-quality leather boots can last a lifetime. This can include resoling, replacing worn heels, repairing tears in the leather upper, re-stitching seams, and conditioning the leather to restore its suppleness and appearance.

The technical skill required for rubber, leather, and cork is immense. Each material reacts differently to adhesives, stitching, and shaping. A cobbler must understand the properties of various rubbers for optimal sole adhesion, the specific needs of different leather types for repair and conditioning, and the delicate nature of cork for footbed restoration. This specialized knowledge lifts repair from a simple fix to a true craft.

Common Footwear Issues That Are Repairable

Many common footwear ailments don’t spell the end for your favorite pair. With the right expertise and materials, most can be effectively repaired, extending the life of your shoes and keeping them out of the landfill.

- Sole Separation: Perhaps the most common issue is when the outsole begins to detach from the midsole or upper. This can be caused by wear, age, or exposure to moisture. Repair typically involves cleaning the surfaces, applying a strong, flexible adhesive (like urethane-based shoe glue or neoprene cement), and clamping the parts together until the bond cures.

- Worn Heels and Soles: Constant walking can wear down the heel caps or the sole tread, leading to uneven wear and discomfort. Repair involves replacing the worn-out sections with new, durable materials, often matched to the original’s specifications for comfort and longevity.

- Broken or Torn Straps: Straps on sandals, heels, or boots can snap, tear, or pull away from their anchor points. Depending on the material (leather, fabric, synthetic), repair can involve stitching, patching, or re-attaching with specialized adhesives and reinforcements.

- Stitching Failure: Over time, the stitching holding various parts of a shoe together can fray or break. This is common in areas of high stress or friction. Repair involves carefully re-stitching the affected areas, often by hand, to restore the shoe’s structural integrity.

- Insole Replacement: While not always visible, worn or damaged insoles can significantly impact comfort and support. Replacing them with new, high-quality insoles can revitalize a pair of shoes and make them feel new.

The Broader Impact of Repair-Focused Business

The benefits of a repair-focused business like NuShoe extend far beyond the individual consumer and their saved pair of shoes. These businesses are powerful engines for positive change, contributing to a more sustainable economy and society on multiple fronts.

One of the most significant impacts is job creation in skilled trades. The demand for hands-on, specialized skills can sometimes diminish in an increasingly automated world. However, repair services require highly trained artisans – cobblers, leatherworkers, and specialized technicians – who possess intricate knowledge and dexterity. Businesses like NuShoe provide stable, meaningful employment opportunities, fostering a workforce with valuable expertise that contributes directly to the circular economy.

Furthermore, repair significantly reduces landfill waste. Every pair of shoes repaired is one less pair contributing to the growing mountains of waste in our landfills. This direct diversion of materials from disposal has a tangible positive effect on environmental health, reducing the need for new landfill sites and mitigating the associated pollution.

Perhaps less obvious, but equally important, is the lower carbon footprint compared to new manufacturing. Producing new shoes, from sourcing raw materials to manufacturing and transportation, is energy-intensive and releases substantial greenhouse gases. Repair, on the other hand, leverages existing materials and requires significantly less energy. By extending the life of products, we reduce the demand for new production, lowering overall carbon emissions associated with footwear.

Finally, repair businesses play a vital role in supporting a local economy. Unlike large-scale manufacturing, which is often globalized, repair services are typically localized. They employ local people, pay local taxes, and usually source materials from regional suppliers where possible. This strengthens community resilience and keeps economic value circulating within the local area.

Quantifying the Environmental Wins

The environmental benefits of shoe repair are not just theoretical; they are quantifiable. By choosing to repair rather than replace, we collectively contribute to significant reductions in resource consumption and pollution.

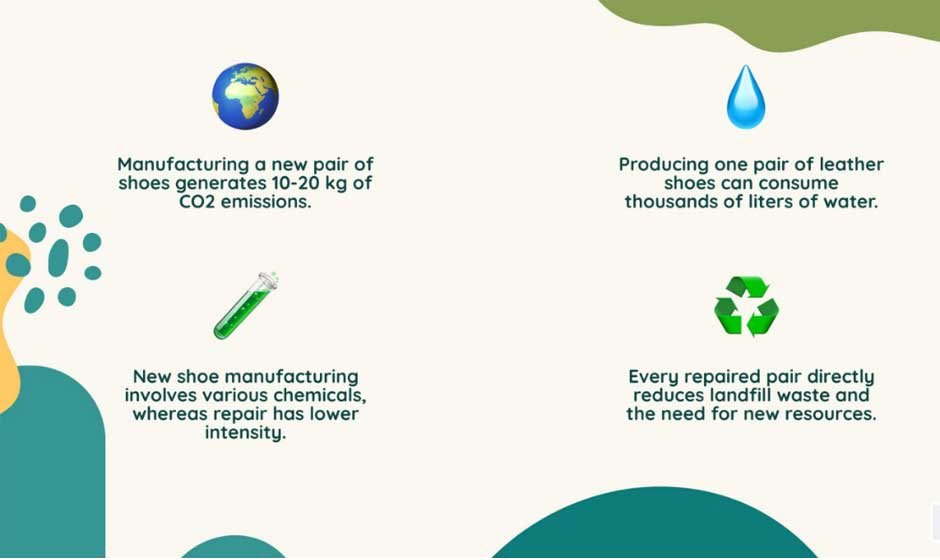

Consider the carbon footprint. Manufacturing a new pair of shoes can generate substantial CO2 emissions, often ranging from 10 to 20 kg per pair, depending on the materials and production processes. This includes raw material extraction, processing, manufacturing, and transportation emissions. Repairing an existing pair, in contrast, involves a fraction of these emissions, primarily related to the energy used in the repair facility and the transport of the shoes to and from the customer. The difference is stark, representing a significant saving in greenhouse gas emissions.

Water savings are another critical benefit. Manufacturing materials like leather and cotton, commonly used in shoes, requires enormous water. For example, producing just one pair of leather shoes can consume thousands of liters of water. Repairing shoes avoids this immense water footprint associated with new material production.

The reduction in chemical use is also noteworthy. New shoe manufacturing often involves various tanning, dyeing, and bonding chemicals. While repairs might use some adhesives, the overall chemical intensity is far lower than that of primary production.

Finally, waste diversion statistics speak volumes. Each repaired pair of shoes is directly diverted from landfills or incinerators, reducing the volume of solid waste that needs to be managed. This saves landfill space and prevents the release of harmful substances that can occur during decomposition or incineration. By embracing repair, we actively participate in a system that values materials and minimizes environmental harm.

Frequently Asked Questions about Sustainable Practices

As more businesses and consumers explore sustainable practices, questions about implementation, cost, and feasibility arise. We address some of these here.

How can a small company start a Sustainable Business model?

Starting on a sustainable journey doesn’t require a complete overhaul overnight. Small companies can adopt a sustainable business model by starting with manageable, impactful steps. First, identify one core principle to focus on: waste reduction, energy efficiency, or product longevity. This might mean offering repair services or designing for durability from the outset for a shoe company. Second, prioritize product durability by sourcing higher-quality materials and employing robust construction methods. This might increase initial costs but leads to longer-lasting products and greater customer satisfaction. Third, offer repair services or partnerships. If in-house repair isn’t feasible, partner with local repair shops to provide this option to your customers. Finally, transparently communicate your sustainability efforts to your customers. Share your journey, your challenges, and your successes. Authenticity resonates with environmentally conscious consumers and builds trust.

Is it more expensive for consumers to repair than to replace?

This is a common misconception, especially in the era of fast fashion. While the initial upfront cost of a quality repair might sometimes seem comparable to a cheap, new replacement, it’s crucial to consider the long-term value. A well-executed repair, particularly on a high-quality item, significantly extends its usable life, often for years. When you factor in the cost per wear or the total cost of ownership over time, repairing almost always proves to be more economical than repeatedly buying cheap replacements. For instance, a $20 repair on a $150 pair of boots that gives them another three years of life is far more cost-effective than buying three new $50 pairs of boots over the same period. The “buy it for life” mindset, where consumers invest in durable goods and maintain them, ultimately saves money and reduces environmental impact.

What makes a product “repairable”?

Several key design and manufacturing choices determine a product’s repairability. Primarily, it’s about using high-quality materials that can withstand wear and tear and are amenable to various repair techniques (e.g., strong leather that can be stitched, durable rubber that accepts adhesives). Secondly, modular design is crucial. Products made of separable components (like a sole that can be detached and replaced) are far easier to repair than fused or integrated ones. Thirdly, the availability of spare parts is essential. Even a well-designed product can become irreparable without replacement components like heels, buckles, or specific sole units. Lastly, standardized construction methods that allow for standard tools and techniques to be used for repair contribute significantly to repairability, making the process more accessible and cost-effective for repair professionals.

Conclusion: Walking the Talk on Sustainability

Our journey through shoe repair and sustainable business models reveals a powerful truth: the circular economy is not just an environmental ideal, but a practical and profitable reality. We’ve seen how changing our relationship with products from “take-make-dispose” to “reduce, reuse, repair, recycle” offers immense benefits for the planet, businesses, and consumers.

NuShoe stands as a shining blueprint for a successful, sustainable enterprise. Their decades of dedication to craftsmanship and their commitment to extending the life of footwear have not only built a thriving business but have also made a significant positive impact on reducing waste and conserving resources. They exemplify how valuing longevity and skilled labor can create a resilient and responsible business model.

The power lies with us, the consumers. Whenever we choose to repair a beloved item instead of replacing it, we vote for sustainability, craftsmanship, and a future where resources are cherished, not squandered. Let us accept the wisdom of extending the life of our possessions, supporting businesses that champion repair, and walking the talk on sustainability, one step, one shoe, at a time.

Leave a Reply