Wiring that is safe and effective is needed for every electrical setup. It’s challenging to make sure that those links stay safe over time. Loose joints or splices that are visible can damage wiring and also put homeowners and workers in danger.

Wiring that is safe and effective is needed for every electrical setup. It’s challenging to make sure that those links stay safe over time. Loose joints or splices that are visible can damage wiring and also put homeowners and workers in danger.

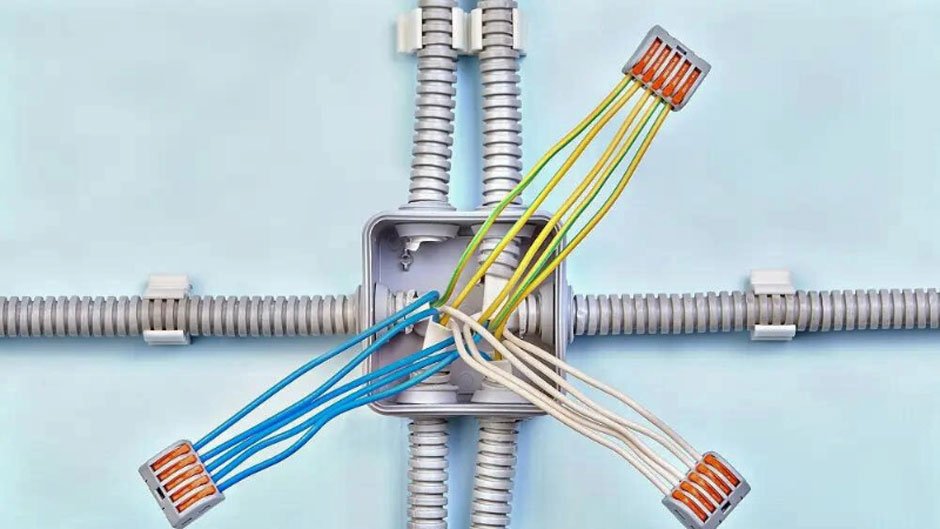

That’s why almost every job needs joint boxes. To show why electrical junction boxes are still important in the business, here are six benefits they offer to installers.

1. Protecting Connections From Damage

Wires that are hidden in ceilings or behind walls can still be damaged. Pests can knock them over, pull them, or even chew on them. As insulation wears away, live lines may become visible, which can be dangerous.

These connections are protected from damage by an electrical joint box. This protects the wiring so it lasts longer, repairs are less likely, and workers don’t have to make as many calls.

2. Reducing the Risk of Fire

First and foremost, electrical fires happen due to connections. If there are splices and they are poorly located or heated, then they can spark. If the spark falls on the dust, wood, and insulation, then the fire will be quick and destructive.

The combination box is a barrier. It shields smoke and heat and prevents them from spreading. As a result, the installers are less anxious: the mix box completes the basic safety standard and ensures that the building is secure.

3. Making Installations Easier to Inspect

Electrical work often involves inspections, but finding where wires connect in a jumbled system takes time and often causes more trouble. Simple checks are hard to do when the plan isn’t clear.

By putting connections in easy-to-reach places, joint boxes speed up and improve the safety of checks. Inspectors and workers can quickly find joins, make sure they are compliant, and move on to the next task.

4. Supporting Safer Repairs and Upgrades

In many cases, repairs or improvements are needed years after the installation of the original facilities. In the absence of junction boxes, electricians may have to work with wires that are difficult to distinguish from one another, fingers prone to injuries, and the peril of starting a fire.

With a box, the joints are kept in one place and are more likely to be discovered and manipulated. The people who put the commodity together can see what they are doing, avoiding potential dangerous side effects.

5. Ensuring Compliance With Standards

The electrical code requires that connections and splices be supported and enclosed in appropriately approved housings. Otherwise, such a violation will lead to a failed inspection, expensive reworkings, and probably legal indictment in case of problems in the future.

Packages of joint boxes are bought to guarantee a conforming foundation. Overall, the impact will be to relieve installers of conflicts and keep the projects on schedule.

6. Creating Professional, Reliable Installations

A bunch of loose wires looks like the work of someone who did it in his garage during his free time, going to an amateur hour. The system may not be secure; a neat and orderly installation makes it seem well-maintained.

Joint boxes can be used for this purpose, and some professionals use them, even though they are not strictly necessary. It is another way of demonstrating one’s professionalism, just as the wires and twines demonstrate one’s thoughtfulness, attention, and long-term well-being.

Why Joint Boxes Are Essential Tools

Joint boxes would appear to be an insignificant part of an electrical system, but their advantages are impressive. For installers, the decision to use joint boxes goes far beyond convenience—it’s about safety, confidence and delivering trusted, reliable systems. Every union needs the right kind of protection, and joint boxes offer just that.

Leave a Reply